Table of Content

Industrial project organisations don’t fail at execution, they struggle with orchestrating complex, fast-moving work across sites, suppliers, compliance, resources, and cash cycles.

When project costing, materials, progress updates, safety documentation, and billing sit across spreadsheets and disconnected systems, decision-making becomes reactive. The result is familiar: schedule slippage, margin leakage, delayed invoicing, and leadership forced to manage risk after the damage is already done.

This is why more industrial project businesses are modernising with a connected Microsoft architecture using Dynamics 365 Business Central as the ERP foundation and layering project delivery capabilities where needed to create a unified, resilient operating model.

This guide outlines a practical, low-risk implementation approach designed specifically for industrial project-based organisations.

Executive Summary

Industrial project delivery requires a system that can connect financial control, materials execution, resource visibility, and project profitability in real time.

Business Central provides the ERP backbone for finance, inventory/warehouse, service management, and project accounting through Jobs. Project Operations can strengthen project-centric capabilities such as bid-to-bill processes, project sales, advanced resourcing, scheduling, and time/expense management. When connected through Dataverse and Power Platform, this combined architecture can deliver standardised workflows, tighter governance, and faster billing with minimal customisation.

With the evolving capabilities of Power Platform and Copilot, industrial project organisations can further accelerate automation, insights, and adoption across site and office teams.

What’s Really Slowing Down Industrial Project Companies Today

- Fragmented data and delayed updates

- Month-end marathons

- Materials movement blind spots

- Low adoption across site, project, and warehouse roles

- Unclear process discipline or weak governance

- Dirty data and inconsistent job structures

- Over-customisation that reduces upgrade readiness

- Underpowered change management

- Business Central as the ERP foundation: Unifies finance, inventory/warehouse, and project accounting (Jobs).

- Project Operations for advanced project lifecycle needs: Connects project sales, pricing/estimation, resourcing, scheduling, time & expense, revenue recognition, and billing.

- How jobs are estimated, costed, and tracked

- How materials move warehouse → site

- How site teams update progress

- How variations and scope changes flow

- How safety and compliance documentation is stored and audited

- How margins and cash cycles are managed

- Customers and vendors

- Item and material masters

- Warehouse and stock positions

- Job structures and history

- Price lists and contract data

- Opening balances

- Resource profiles

- Create → plan → execute → invoice a project

- Track material allocation and consumption at site

- Approve purchases and variations

- Submit and validate time/expense

- Monitor job profitability mid-flight

- Attach safety/compliance documents

- Generate live cash and margin forecasts

- Project managers tracking cost, progress, and margin

- Warehouse teams updating allocation and movement

- Procurement managing approvals and supplier workflows

- Finance accelerating billing and reconciliation

- Leadership interpreting KPIs and exception dashboards

- Daily performance monitoring

- Minor fixes and workflow refinements

- Dashboard tuning

- Continuous coaching and support

- Early optimisation opportunities

- Risk: Fragile upgrades and long-term complexity.

- Fix: Exhaust standard capabilities before extending.

- Risk: Site and warehouse adoption gaps.

- Fix: Role-based UX, practical training, quick wins, visible dashboards.

- Risk: Low trust and poor decisions.

- Fix: Cleanse, validate, and pilot with real project scenarios.

- Risk: Weak understanding of job costing, warehouse-to-site flows, and compliance.

- Fix: Choose a Microsoft partner who follows Success by Design and has industrial project credentials.

- Risk: Timeline and budget blowouts.

- Fix: Phase delivery.

- Phase 1: Projects, inventory, core finance, approvals.

- Phase 2: Power BI, advanced automation, mobility, Copilot-led productivity.

- Low-code site forms and mobile capture

- Automated approvals and notifications

- Embedded Power BI dashboards for live margin and materials visibility

Jobs, materials, and margin insights often live across spreadsheets, emails, and siloed tools. Site teams operate with outdated plans and inconsistent cost visibility — increasing rework risk and eroding confidence in reporting.

Manual reconciliations, inconsistent accruals, and scattered approvals delay true profitability assessment. By the time leadership sees the numbers, the project outcome is already shaped.

Warehouse-to-site flows frequently lack traceability. Without clarity on what was allocated, consumed, returned, or wasted, delays increase and cost control becomes reactive.

A connected ERP doesn’t just digitize reporting; it changes how industrial project businesses make decisions daily.

Why Implementations Fail (and How to Avoid It)

ERP transformations rarely fail due to product limitations. They fail because organisations underestimate readiness and adoption.

In industrial projects, these risks are amplified by live site execution, time pressures, and multi-location coordination.

The safest path forward is a structured, best-practice delivery approach aligned with Microsoft’s implementation guidance (Success by design) including architecture reviews, data readiness, testing discipline, and go-live governance.

Architecture That Works: Business Central + Project Operations

Industrial project businesses typically use Microsoft in one of two models:

Architecture That Works: Business Central + Project Operations

Industrial project businesses typically use Microsoft in one of two models:

Business Central as the ERP foundation

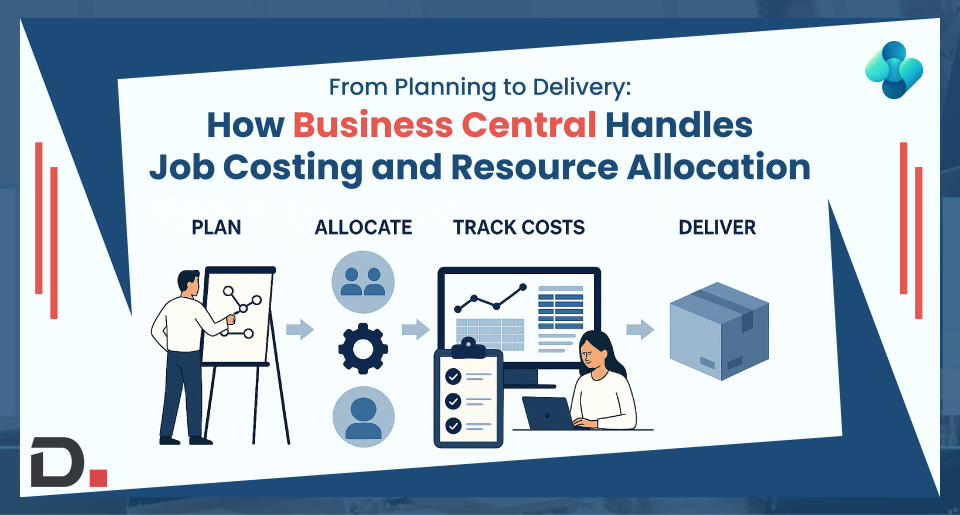

Business Central unifies finance, inventory/warehouse, and project accounting (Jobs). It supports project budgeting, resource usage, cost tracking, and time-and-material or fixed-fee billing alongside strong financial controls.

Project Operations for advanced project lifecycle needs

Connects project sales, pricing/estimation, resourcing, scheduling, time & expense, revenue recognition, and billing for project‑centric businesses.

How they fit together

Many industrial firms use Business Central Jobs for cost and margin control and layer Project Operations for bid-to-bill and advanced resourcing connected through Dataverse and Power Platform integration patterns.

This approach allows organisations to strengthen project delivery maturity without disrupting the ERP foundation.

A Proven Implementation Roadmap for Industrial Projects

Successful industrial implementations follow a disciplined sequence that prioritises stability, adoption, and phased value.

1) Business Assessment: Map reality before digitizing

A meaningful assessment examines operational truth, not just system requirements.

This includes:

Why this matters:You can’t digitize a broken process. You must identify bottlenecks before configuring the platform.

2) Solution Design: Configure standard first

Industrial project success depends on disciplined configuration before customisation.

Typical priority capability areas include:

In Business Central: Jobs, inventory/warehouse flows, purchasing approvals, and billing.

Where Project Operations is used: sales to delivery workflows, pricing & estimation, resource scheduling, time/expense, pro‑forma and revenue recognition.

Aim for manual to automated, hidden to visible, reports to dashboards, then customize only for high‑value gaps.

3) Data Migration: Clean data = clean outcomes

Data quality is a core adoption driver in project environments.

Key datasets typically migrated include:

Why this matters: Clean data reduces shadow systems and helps teams trust project and margin dashboards early.

4) Testing: Real-life scenarios only

Industrial testing must reflect real execution conditions.

High-value scenarios include:

Why this matters: Testing under real workflows reduces go-live risk and builds confidence across operational teams.

5) Training and change: Adoption drives ROI

Training should be role-based and operationally grounded.

This includes enablement for:

Why this matters: An ERP becomes valuable when it becomes daily behaviour.

6) Go-live + support (30–60 days)

The post-launch stabilisation phase is where long-term success is secured.

Expect a structured focus on:

Why this matters: This is where the platform moves from “implemented” to “embedded.”

Key Risks and Mitigations

Over-customisation

Team resistance

Dirty data

Wrong partner

Scope creep

Site Reality: Materials, Warehousing & Traceability

Industrial projects depend on accurate warehouse → site movements and real‑time consumption. BC supports bins, warehouse shipments, inventory picks/movements, directed pick/put‑away with configuration levels that scale as you mature—critical for fewer delays, tighter margin control, and better auditability.

Power Platform and Copilot: Accelerators That Matter

Once the operational core is stable, industrial businesses often extend value through:

Power Platform

Copilot capabilities

Included with BC Online- chat‑assisted workflows, bank reconciliation assistance, product information creation, and more; Microsoft continues to expand capabilities across release waves.

What Many Leaders Begin to See Within 90 Days

With a well-executed rollout and strong adoption, industrial project organisations often experience:

Faster job cost visibility and margin decision-making

Reduced material-related delays with clearer warehouse-to-site execution

Smarter resource planning and improved billing predictability

Lower administrative burden through automated approvals and role-based workflows

Stronger leadership confidence in real-time dashboards

Why Dynamics Square

ERP success is not only about choosing the right Microsoft platform it’s about implementing it with industry context, structured governance, and adoption-first execution.

As a designated partner for Microsoft dynamic 365, Dynamics Square brings deep industrial project understanding, Microsoft‑aligned delivery, and a Success by Design‑driven approach from assessment and solution blueprint to clean data, role‑based adoption, and phased value realisation.

Your ERP foundation may come from Microsoft.

Your transformation outcomes depend on the partner who delivers it with clarity and accountability.

Conclusion: The Future Belongs to Connected Industrial Project Operations

Industrial project businesses that modernise with Business Central and project-centric capabilities gain more than better reporting.

They build a connected operating model where projects, materials, resources, compliance and finance move in sync, enabling predictable execution, stronger margin control, and scalable growth.

If your operations are still driven by disconnected tools and profitability is confirmed only after month-end, it’s time to move to a unified, cloud-ready foundation.

Book a free 30-minute consultation with Dynamics Square to explore an implementation blueprint tailored to your industrial environment, operating model, and growth goals.

Looking for Localised Support Partner?

Let's collaborate with Australia’s trusted localised support partner to maximise your business potential! Let us drive success in your business with our Dynamics 365 Support Services.

Disclaimer– “All data and information provided on this blog is for informational purposes only. Dynamics Square / MPG Business Information Systems Pvt. Ltd. makes no representations as to accuracy, completeness, currentness, suitability, or validity of any information on this site and will not be liable for any errors, omissions, or delays in this information or any losses, injuries, or damages arising from its display or use.”