Table of Content

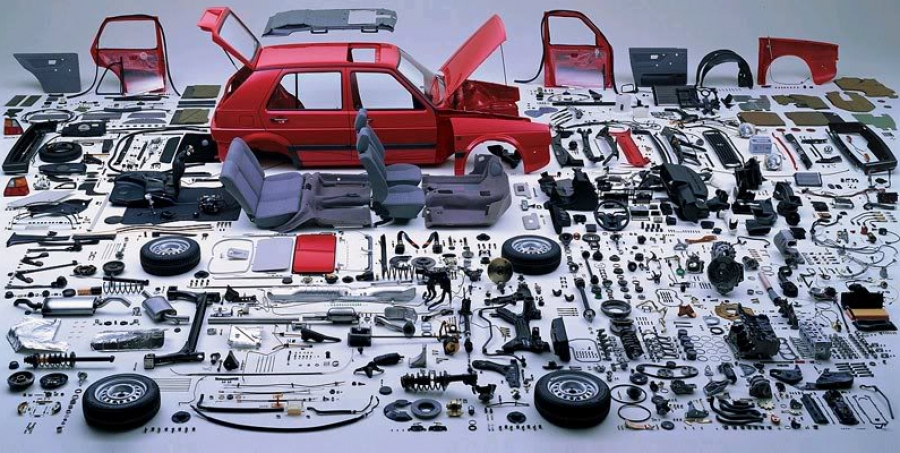

The manufacturing industry plays a pivotal role in the global economy, driving innovation, generating employment, and meeting the demands of diverse markets. However, like any other sector, it faces numerous challenges that can hinder its growth and efficiency.

These challenges range from process complexities to inventory management, rising costs, and the need for streamlined operations.

To stay competitive in today's fast-paced market, manufacturing companies must embrace technological solutions that enhance productivity and streamline processes. One such solution that has emerged as a game-changer is Microsoft Dynamics 365 Business Central.

In this blog, we will explore the major challenges faced by the manufacturing industry. We’ll also explore how Business Central can be the key to overcoming these obstacles.

Get ready to embark on a transformative journey as we explore how Business Central implementation can revolutionize the manufacturing landscape.

Let’s first explore major roadblocks that manufacturing business leaders may face.

Unfolding the Complexities: Manufacturing Industry Challenges

The manufacturing industry is a dynamic and vital sector, but it faces a myriad of challenges that require constant innovation and adaptation. "Unfolding the Complexities: Manufacturing Industry Challenges" delves into the multifaceted issues plaguing this sector.

Supply chain disruptions, driven by global events like pandemics and natural disasters, disrupt production and demand robust mitigation strategies. Maintaining stringent quality control amidst material variations is another hurdle that manufacturers must navigate.

Skilled labor shortages and rapidly advancing technology further amplify these challenges. Environmental regulations demand sustainable practices, while global competition requires constant innovation and cost-efficiency. In this complex landscape, understanding and addressing these challenges are crucial for sustainable growth and success.

Are you running a manufacturing business? If so, go ahead and check do these below-mentioned challenges sound familiar.

Technological Advancements

As technology evolves rapidly, manufacturers need to continuously invest in automation, artificial intelligence, and other emerging technologies to remain competitive. Adapting to these changes while ensuring a smooth transition can be a significant challenge.

Solution

Overcoming technological challenges in manufacturing demands a proactive approach. Prioritize continuous employee training, fostering an innovative culture, and forging strategic collaborations.

Develop a technology adoption roadmap aligned with business objectives, leveraging data analytics, AI, and automation for improved efficiency. Implement digital twins and cybersecurity measures to protect operations.

Supply Chain Disruptions

Disruptions in the supply chain, such as natural disasters, geopolitical issues, and unexpected events like the COVID-19 pandemic, can lead to delays, increased costs, and production interruptions. Manufacturers must establish resilient supply chains to mitigate these risks.

Solution

To overcome supply chain disruption challenges in manufacturing, diversify suppliers, maintain safety stock, and deploy real-time monitoring tools. Develop contingency plans for rapid response, foster strong supplier relationships, and consider local sourcing.

Embrace digitalization for increased visibility and agility, allowing for quicker adaptation to unforeseen disruptions. Collaborate with suppliers to share risk and invest in risk mitigation strategies like warehousing and transportation redundancy.

Global Competition

The manufacturing industry faces intense global competition, with companies from various countries vying for market share. Cost-effective production and maintaining quality standards are critical to compete on a global scale.

Solution

To overcome global competition challenges in manufacturing, focus on niche markets, differentiate products through innovation, and leverage automation to reduce labour costs. Embrace digital technologies for efficiency gains, invest in skilled labour training, and establish efficient supply chains.

Strategic partnerships and collaborations can also help access new markets and share resources, enhancing competitiveness in the global manufacturing landscape.

Labor Shortages

Many manufacturing companies struggle to find skilled labor to fill essential roles. This shortage can slow down production and increase labor costs. Training and retaining skilled workers are ongoing challenges.

Solution

Companies can invest in employee training and development programs, adopt automation and robotics to augment the workforce, and implement flexible work arrangements to attract and retain skilled talent.

Additionally, forging partnerships with educational institutions and offering competitive compensation packages can help address this challenge effectively.

Environmental Regulations

Governments worldwide are imposing stricter environmental regulations. Manufacturers must comply with these regulations, which often require costly equipment upgrades and changes in production processes to reduce environmental impact.

Solution

Companies should proactively stay informed about evolving regulations, invest in sustainable practices and clean technologies, conduct regular environmental audits, and establish robust compliance programs.

Collaboration with regulatory agencies, and industry associations, and the adoption of environmentally friendly practices can help manufacturers ensure compliance while reducing their environmental footprint.

Cybersecurity Threats

With increased connectivity and digitalization, manufacturers are vulnerable to cyberattacks. Protecting sensitive data, production processes, and intellectual property from cyber threats is a growing concern.

Solution

Manufacturing companies should implement robust security protocols, conduct regular employee training, and maintain up-to-date software. Employ network segmentation to isolate critical systems, monitor for anomalies, and establish an incident response plan.

Collaborate with cybersecurity experts to assess vulnerabilities and ensure compliance with industry standards, safeguarding sensitive data and operations from potential breaches.

Rising Costs

Fluctuations in the prices of raw materials, energy, and transportation can significantly impact manufacturing costs. Manufacturers must manage and mitigate these cost increases to maintain profitability.

Solution

Manufacturers should focus on cost-effective strategies like process optimization, automation, and lean manufacturing principles. Negotiate favorable supplier contracts, embrace energy-efficient technologies, and invest in employee training. Continuously monitor expenses, analyze cost drivers, and explore sustainable practices. Implementing cost-saving measures while maintaining product quality is essential to mitigate the impact of rising costs in the manufacturing industry.

Lack of Automation

Manual processes often lead to reduced efficiency, higher labor costs, and inconsistent product quality. Moreover, safety concerns persist in handling hazardous tasks. Manual methods may limit production capacity, hinder competitiveness, and miss opportunities for data-driven optimization.

Solution

To address the absence of automation in manufacturing, a strategic roadmap is essential. Begin with a comprehensive assessment and set well-defined goals. Allocate a budget, select appropriate technology, and invest in workforce training. Pilot automation in controlled environments, ensuring seamless integration and prioritizing safety measures. Engage employees through change management and monitor system performance closely for ongoing improvements.

As successes accumulate, expand automation throughout your operations, collaborate with industry partners, adhere to regulations, and maintain cybersecurity. Continuous learning keeps manufacturing processes agile and competitive.

Would you like to win over your competitors by overcoming all the manufacturing challenges?

Our Dynamics 365 Consultants would help you explore Business Central for Manufacturing to address all the obstacles to stay ahead.

Related Posts - ERP Systems for Manufacturing

Conclusion

The manufacturing industry is no stranger to challenges, but with the right technology in place, these obstacles can be transformed into opportunities for growth and success. So, the right technology is Microsoft Cloud for Manufacturing.

It’s an all-in-one business solution to address the major challenges faced by the manufacturing industry. Embracing Dynamics 365 SCM for the manufacturing industry can help manufacturers achieve higher operational efficiency, reduce costs, meet compliance requirements, and respond swiftly to changing market conditions.

By implementing this powerful tool, manufacturers can position themselves as industry leaders, ready to capitalize on emerging opportunities and tackle future challenges head-on.

In today's competitive landscape, this cloud-based ERP solution is undoubtedly a key to unlocking the manufacturing industry's full potential and driving it towards sustainable growth and success.

Ready to revolutionize your manufacturing processes and take your business to new heights?

Switch to Dynamics 365 for Manufacturing now!

Related Posts - How Dynamics 365 Business Central Can Transform the Manufacturing Sector?

Witness a scalable transformation

Experience real-time synchronisation and flexibility with a consistent view across your business.

Disclaimer– “All data and information provided on this blog is for informational purposes only. Dynamics Square / MPG Business Information Systems Pvt. Ltd. makes no representations as to accuracy, completeness, currentness, suitability, or validity of any information on this site and will not be liable for any errors, omissions, or delays in this information or any losses, injuries, or damages arising from its display or use.”