Table of Content

Welcome to our exploration of the intricate world of Supply Chain Management (SCM), a critical component in the success of modern businesses. In this blog, we delve into the fundamental question: What is Supply Chain Management? Unravelling the complexities of SCM, we'll dissect the methods, processes, and systems that underpin the seamless flow of goods and services from production to consumption.

From procurement to distribution, our journey will navigate the intricate web of suppliers, manufacturers, and logistics, shedding light on the strategies and technologies that optimize efficiency.

Join us as we demystify SCM, offering insights into its evolving landscape and its pivotal role in today's dynamic business environment.

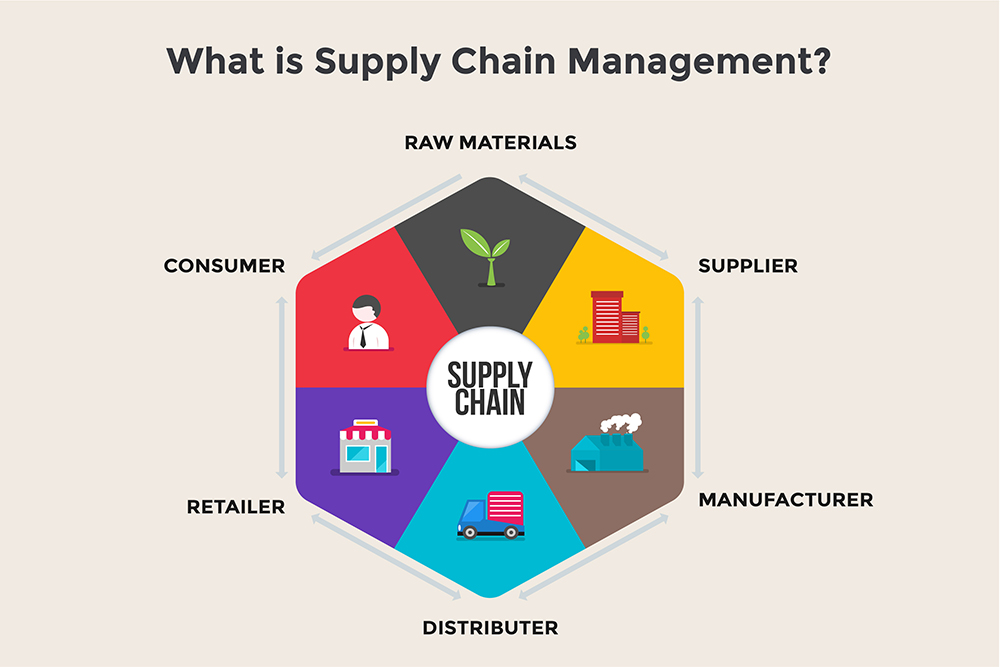

What is Supply Chain Management?

Supply Chain Management (SCM) is the strategic orchestration of the entire production-to-consumption journey, defining the processes that streamline the flow of goods and services. At its core, SCM encompasses procurement, production, and distribution, ensuring optimal efficiency and cost-effectiveness.

It's the art of synchronizing suppliers, manufacturers, and logistics into a cohesive network, navigating complexities to meet consumer demands. SCM isn't just a business function; it's a dynamic strategy that adapts to market shifts and technological advancements. In this exploration, we unravel the essence of SCM, deciphering its significance in the contemporary business landscape.

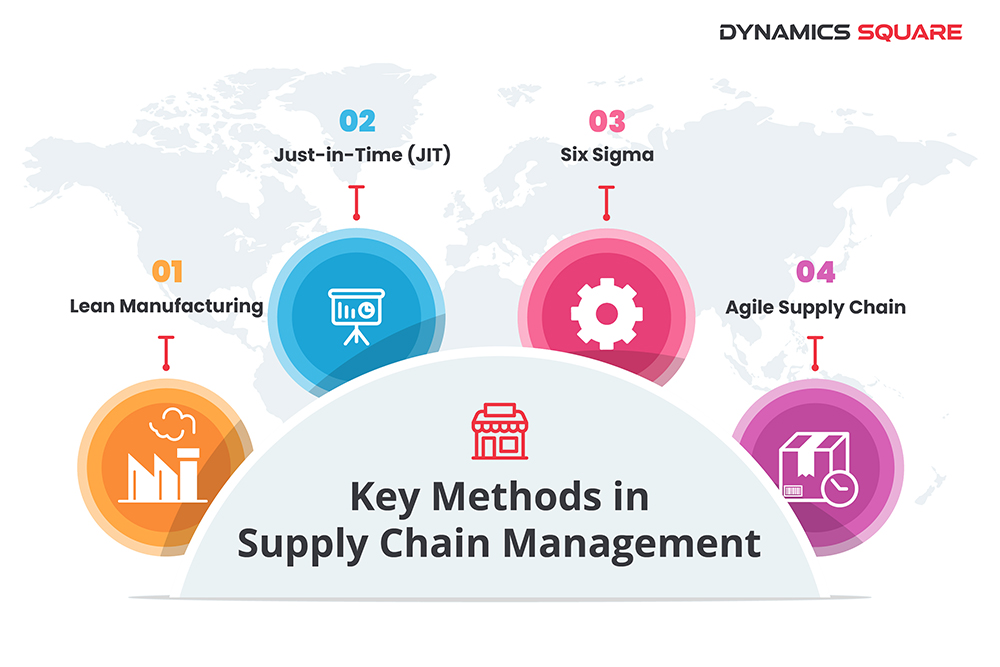

Key Methods in Supply Chain Management

In the dynamic landscape of SCM, several methods contribute to its successful implementation. These methodologies are designed to enhance efficiency, reduce costs, and create a responsive and agile supply chain.

Lean Manufacturing: Minimizing Waste

Lean manufacturing is a cornerstone of SCM, aiming to minimize waste while maximizing efficiency. This method emphasizes the elimination of non-value-added activities, reducing excess inventory, and optimizing production processes. By streamlining operations, companies can respond swiftly to changes in demand and maintain a cost-effective supply chain.

Just-in-Time (JIT): Precision in Production

JIT is a method where products are manufactured or delivered just in time to be sold or used. This approach reduces the need for large inventories, lowering carrying costs and minimizing the risk of obsolete stock. JIT relies on accurate demand forecasting, efficient communication within the supply chain, and robust relationships with suppliers to ensure a seamless and responsive production process.

Six Sigma: Quality Assurance

Six Sigma is a data-driven methodology that focuses on minimizing defects and improving the quality of processes. In the context of SCM, Six Sigma principles can be applied to enhance the reliability of the entire supply chain, ensuring that products meet or exceed customer expectations. By reducing variability and defects, companies can achieve a higher level of customer satisfaction and operational efficiency.

Agile Supply Chain: Adapting to Change

The agile supply chain methodology prioritizes adaptability and responsiveness. In today's dynamic business environment, where market conditions can change rapidly, an agile supply chain can quickly adjust to fluctuations in demand, supply chain disruptions, or changes in customer preferences. This approach often involves collaboration, real-time data sharing, and flexible manufacturing processes.

Related Posts - Major Trends to Look Forward to in the World of Supply Chain Management

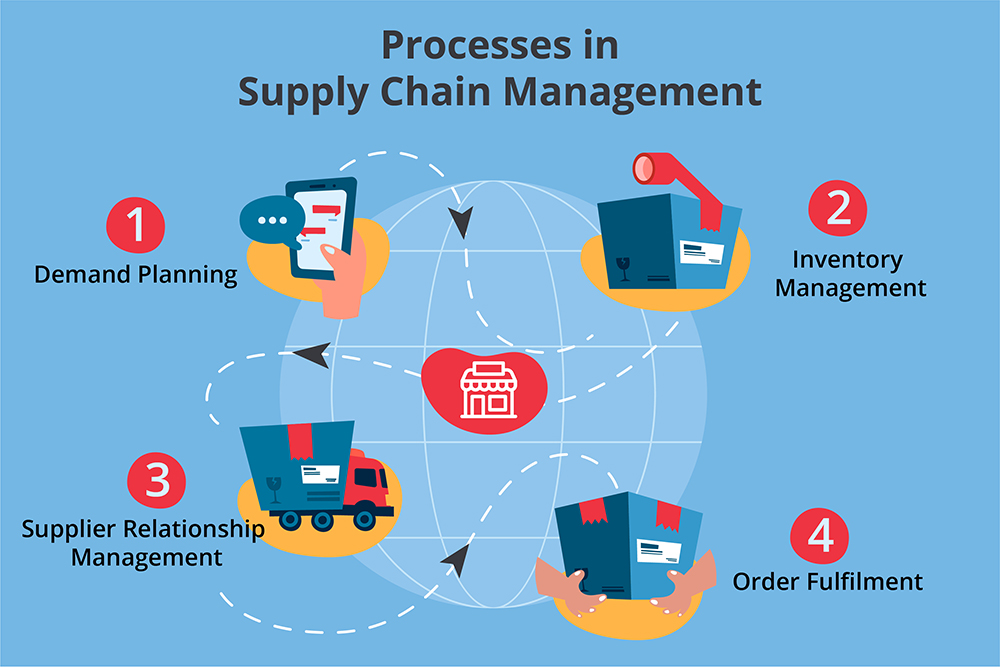

Processes in Supply Chain Management

Beyond methodologies, the success of SCM is contingent on well-defined processes that govern the end-to-end journey of products and services.

Demand Planning: Anticipating Customer Needs

Demand planning is the process of forecasting customer demand for products or services. Accurate demand forecasts enable organizations to align production and distribution with market requirements, preventing overstock or stockouts. Advanced analytics, artificial intelligence, and historical data analysis play crucial roles in enhancing the precision of demand planning processes.

Inventory Management: Balancing Act

Effective inventory management involves maintaining optimal stock levels to meet customer demand while minimizing carrying costs. This process requires a delicate balance to prevent overstock situations that tie up capital or stockouts that could result in lost sales. Advanced inventory management systems utilize real-time data and predictive analytics to optimize stock levels and improve overall supply chain efficiency.

Supplier Relationship Management (SRM): Collaboration for Success

Supplier Relationship Management focuses on building and maintaining positive relationships with suppliers. A collaborative and transparent relationship with suppliers enhances communication, reduces lead times, and fosters innovation. An effective SRM process involves performance evaluations, risk management, and strategic alignment to ensure that suppliers are integral partners in achieving supply chain objectives.

Order Fulfilment: Meeting Customer Expectations

Order fulfilment is the process of receiving, processing, and delivering customer orders. This encompasses everything from order capture to shipment and delivery. An efficient order fulfilment process is crucial for customer satisfaction, and modern technologies like automation, robotics, and advanced warehouse management systems play pivotal roles in streamlining these operations.

Related Posts - How ERP Systems Enhance Supply Chain Management?

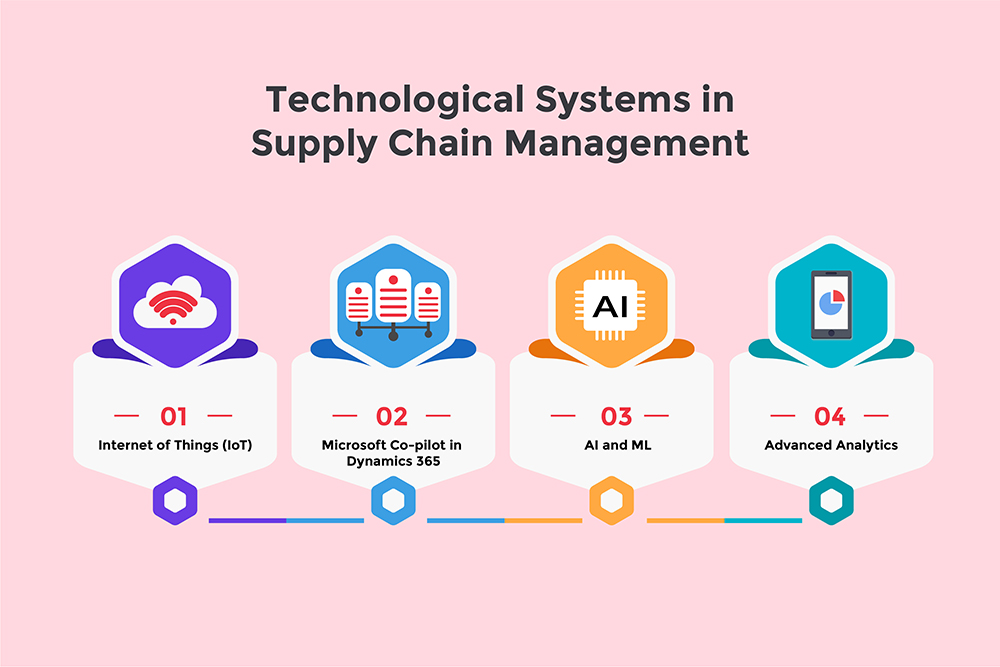

Technological Systems in Supply Chain Management

Technology plays a transformative role in modern SCM, providing tools and systems that enhance visibility, connectivity, and overall efficiency.

Internet of Things (IoT): Real-time Monitoring

IoT devices, such as sensors and RFID tags, provide real-time visibility into the movement and condition of products within the supply chain. This data allows for proactive decision-making, reducing the risk of disruptions, and improving overall supply chain performance.

Microsoft Co-pilot in Dynamics 365: Revolutionizing Collaboration and Development

Microsoft Co-pilot, an innovative AI-powered tool, has emerged as a game-changer in the supply chain domain. Leveraging machine learning capabilities, Co-pilot assists in code writing, accelerating the development of supply chain management software. This not only enhances the speed of system implementation but also ensures that SCM solutions are tailored to the unique needs of businesses. By fostering collaboration and reducing development timelines, Microsoft Co-pilot contributes to the evolution of efficient and customized technological systems within the supply chain, ushering in a new era of streamlined operations.

Artificial Intelligence (AI) and Machine Learning (ML): Predictive Analytics

AI and ML algorithms analyse vast datasets to provide predictive insights and optimize decision-making processes. In SCM, these technologies are applied to demand forecasting, route optimization, and inventory management, among other areas. The result is a more adaptive and intelligent supply chain that can anticipate and respond to changing conditions.

Related Posts - How AI is Redefining Your Supply Chain?

Advanced Analytics: Data-Driven Decision Making

Advanced analytics involves the use of statistical models and algorithms to extract actionable insights from large datasets. In SCM, advanced analytics can be applied to optimize supply chain processes, identify inefficiencies, and improve overall performance. Data-driven decision-making is a cornerstone of modern SCM, enabling companies to continuously refine their operations.

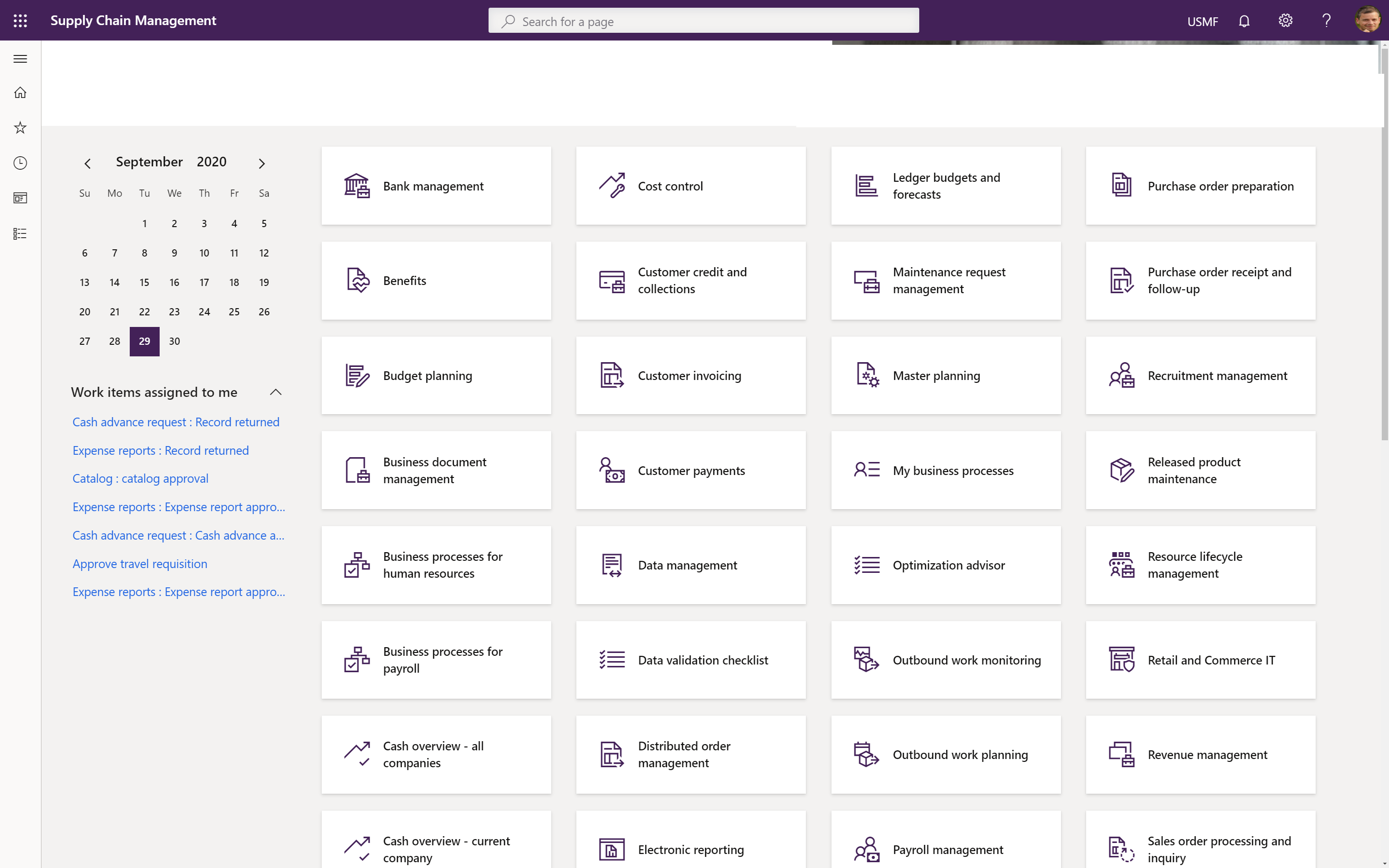

How does Dynamics 365 Manage your Supply Chains effectively?

In the intricate landscape of Supply Chain Management (SCM), the role of technology cannot be overstated. Microsoft Dynamics 365 emerges as a powerhouse, offering a comprehensive suite of tools designed to enhance the efficiency, visibility, and adaptability of supply chain processes. Here's a deep dive into how Dynamics 365 effectively manages your supply chains:

Unified Platform for End-to-End Visibility

Dynamics 365 provides a unified platform that integrates various facets of supply chain management into a seamless whole. From procurement and production to distribution and beyond, the platform ensures end-to-end visibility, enabling stakeholders to monitor and manage every stage of the supply chain in real time.

Demand Planning and Forecasting

Accurate demand planning is critical for effective supply chain operations. Dynamics 365 leverages advanced analytics and machine learning algorithms to analyze historical data, market trends, and external factors. This enables businesses to generate more accurate demand forecasts, align production and inventory levels, and ultimately reduce the risk of overstock or stockouts.

Inventory Optimization

Dynamics 365 aids in optimizing inventory levels, striking a delicate balance between meeting customer demand and minimizing carrying costs. Through real-time data analysis, businesses can make informed decisions about inventory replenishment, reduce excess stock, and ensure products are available when and where they are needed.

Supplier Relationship Management (SRM)

Effective supplier relationships are crucial for a resilient supply chain. Dynamics 365 facilitates Supplier Relationship Management by providing tools for transparent communication, performance evaluations, and risk management. Businesses can strengthen collaborations with suppliers, ensuring a steady and reliable flow of materials.

Streamlined Order Fulfilment

Dynamics 365 streamlines the order fulfillment process, from order capture to delivery. By automating workflows and providing real-time updates on inventory levels, order status, and shipment tracking, the platform enhances the speed and accuracy of order processing, contributing to improved customer satisfaction.

Advanced Analytics for Informed Decision-Making

The platform's robust analytics capabilities empower businesses with actionable insights. Dynamics 365 allows users to analyze vast datasets, identify trends, and make data-driven decisions. This not only enhances overall supply chain performance but also provides a foundation for continuous improvement and adaptation to changing market conditions.

Collaboration and Communication

Effective communication and collaboration are essential for supply chain success. Dynamics 365 offers collaboration tools that facilitate communication between different stakeholders, both internal and external. This fosters a collaborative environment, ensuring that all parties involved in the supply chain are well-informed and aligned with the overall objectives.

Continuous Updates and Innovations

Microsoft is committed to keeping Dynamics 365 at the forefront of technology. Continuous updates and innovations ensure that businesses leveraging the platform have access to the latest tools and features. This commitment to staying current with industry trends and technological advancements positions Dynamics 365 as a future-ready solution for evolving supply chain challenges.

Related Posts - Ways to Streamline Supply Chain Management using Dynamics 365 ERP

Conclusion

In conclusion, Dynamics 365 stands as a robust and integrated solution for managing supply chains effectively. By combining advanced analytics, IoT integration, and a user-friendly interface, Dynamics 365 empowers businesses to optimize their supply chain processes, adapt to changing market dynamics, and ultimately drive success in the competitive business landscape.

Want to explore Dynamics 365 Supply Chain Management in action?

Connect with Dynamics Square team!

Witness a scalable transformation

Experience real-time synchronisation and flexibility with a consistent view across your business.

Disclaimer– “All data and information provided on this blog is for informational purposes only. Dynamics Square / MPG Business Information Systems Pvt. Ltd. makes no representations as to accuracy, completeness, currentness, suitability, or validity of any information on this site and will not be liable for any errors, omissions, or delays in this information or any losses, injuries, or damages arising from its display or use.”