Table of Content

Hey there, manufacturing industry experts! Are you struggling with your supply chain to satisfy customer demands with minimum waste and in less time? If the answer is yes, it's time to leverage lean manufacturing to gain a competitive advantage.

Now the real challenge is to achieve the full potential of lean manufacturing in your processes for optimum business efficiency. Therefore, we are here to help you analyse your specific business requirements and provide you with the best solution for the success of lean manufacturing operations.

The game-changing approach of lean manufacturing in Microsoft Dynamics 365 helps you streamline manufacturing processes, eliminate waste, and maximise efficiency. These capabilities of Dynamics 365 empower you to optimise every step of the production system and utilise resources to their fullest potential.

Join us as we delve into the world of lean manufacturing. Get ready to satisfy customer demand on time while minimising waste with real-time Dynamics 365 tools and advanced strategies.

What is Lean Manufacturing?

Lean manufacturing is an approach that prioritises productivity while minimising waste in manufacturing systems. The lean manufacturing practice reduces waste and inventory costs by producing goods based on demand rather than excessive stocking.

Lean manufacturing offers numerous advantages, such as shorter lead times, decreased operating expenses and enhanced product quality. You can create customer value and achieve continuous process improvement with lean project management principles, techniques, and tools.

Lean manufacturing introduces Kanban, which acts as a signal for demand requirements. You will have complete control over inventory and produce goods only when needed. No more excessive stockpiling or overproduction. It's all about meeting customer demand precisely and efficiently.

What is Lean Manufacturing in Dynamics 365?

Lean manufacturing is an ongoing journey of improvement aimed at efficiently producing what the customer desires and at the time of their requirement. Dynamics 365 incorporates production flows, activities, and Kanban rules as integral components of its lean manufacturing architecture.

Lean Manufacturing can be implemented within a Dynamics 365 manufacturing environment that blends different supply, production, and sourcing strategies. These strategies encompass production orders, batch orders for process industries, purchase orders and transfer orders.

To get a clear idea of lean manufacturing we need to first understand its principles.

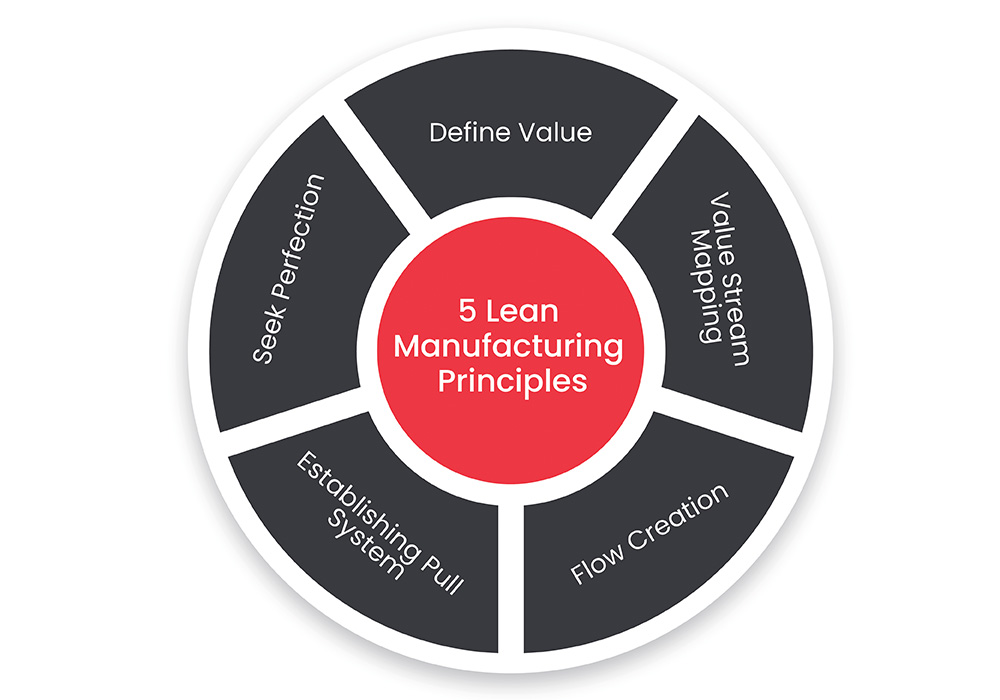

What are the Lean Manufacturing Principles?

The lean manufacturing principle considers waste as anything that lacks value from the customer's perspective and is not deemed worthy of payment. The five core principles of lean manufacturing have influenced the production system worldwide.

Define Value

The determination of value is based on the customer's viewpoint and willingness to pay for products or services. Manufacturers create this value by striving to eliminate waste and minimise costs, allowing them to achieve the optimal price for customers while maximising profit.

With Dynamics 365, companies can effectively manage quality and track key metrics such as defects, cycle times and production yields. The platform also offers robust analytics and reporting features to generate reports, offering valuable insights into customer preferences and production efficiency.

Value Stream Mapping

A value stream encompasses the entire life cycle of a product, spanning from its design to the customer's usage and eventual disposal. The Value Stream Mapping (VSM) tool visually maps the entire product flow. Through mapping, it becomes simpler to identify and minimise non-value-added steps in the process.

Dynamics 365 tools streamline operations, cut costs and minimise lead times by automating numerous manual tasks in the manufacturing process. The platform enables real-time inventory tracking, allowing businesses to maintain optimal inventory levels efficiency.

Flow Creation

Flow creation involves eliminating functional barriers to enhance lead times, ensuring that processes can proceed smoothly and with minimal delays or waste. When there is a disruption in the production process, it incurs costs. Creating flow ensures a continuous, uninterrupted stream of production or service delivery.

With real-time data monitoring, Dynamics 365 empowers businesses to identify bottlenecks that impede production and hinder meeting customer demand. The production scheduling module simplifies optimising company resources, enabling producers to ensure efficient resource utilisation.

Establishing Pull System

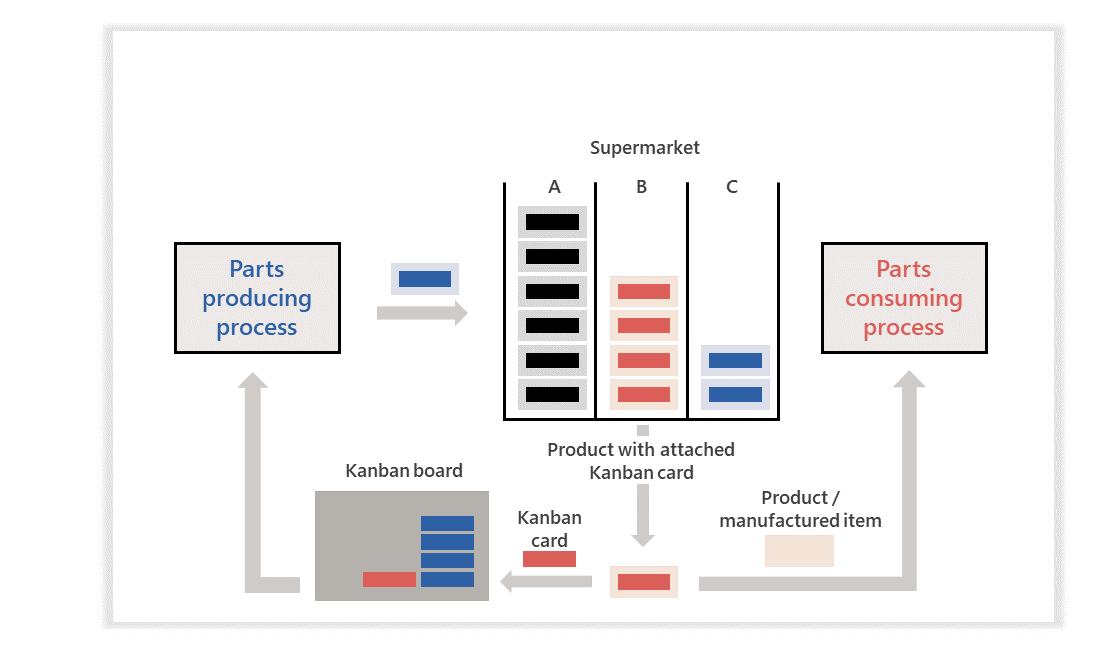

A pull system operates by fulfilling a customer's order from the shipping department, subsequently triggering the manufacturing of new items and signalling the need for additional supply purchases. Lean manufacturing tools, such as Kanban, can assist in implementing a pull system that effectively manages the material flow within the production.

Dynamics 365 facilitates pull systems through visual Kanban boards, serving as a signalling system. The board informs businesses when to increase production or replenish inventory.

Seek Perfection

Lean manufacturing emphasises ongoing assessment, improvement, and waste elimination in pursuit of an optimised value stream. Continuous improvement, ingrained in the organisational culture, involves measuring metrics like lead times, production cycles, throughput, and cumulative flow.

Dynamics 365 helps in the successful implementation of lean manufacturing enhancements through its process mapping and root cause analysis tools. With these tools, teams can validate the efficiency of improvements and establish new operating standards.

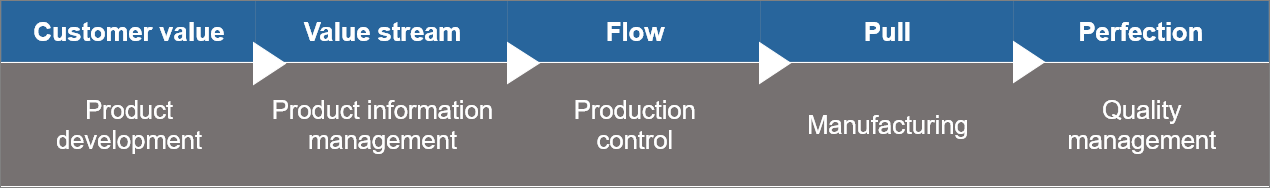

Lean Manufacturing in Dynamics 365 Supply Chain

Lean Manufacturing is a production philosophy focusing on reducing waste, improving efficiency, and maximising customer value. In Dynamics 365 Supply Chain Management, Microsoft offers various features enabling organisations to implement and model lean manufacturing principles.

Above image shows how lean concepts can work with features in Supply Chain Manufacturing.

Modeling Manufacturing and Logistics Processes as Production Flows

Organisations can model their manufacturing and logistics processes as production flows within Dynamics 365 Supply Chain Management to establish a lean manufacturing foundation. You can streamline and analyse these processes to reduce waste by enhancing material and information flow.

Production flows are sequences of activities that describe the movement of materials and value-added operations. Creating versions of production flows with defined time requirements can calculate cycle times for each activity, and multiple versions can be used to drive process improvements.

Leveraging Kanban to Indicate Demand Needs

A key aspect of lean manufacturing is implementing a pull system, where goods are produced based on actual demand. A pull system minimises lead times and excess inventory by producing goods only when needed.

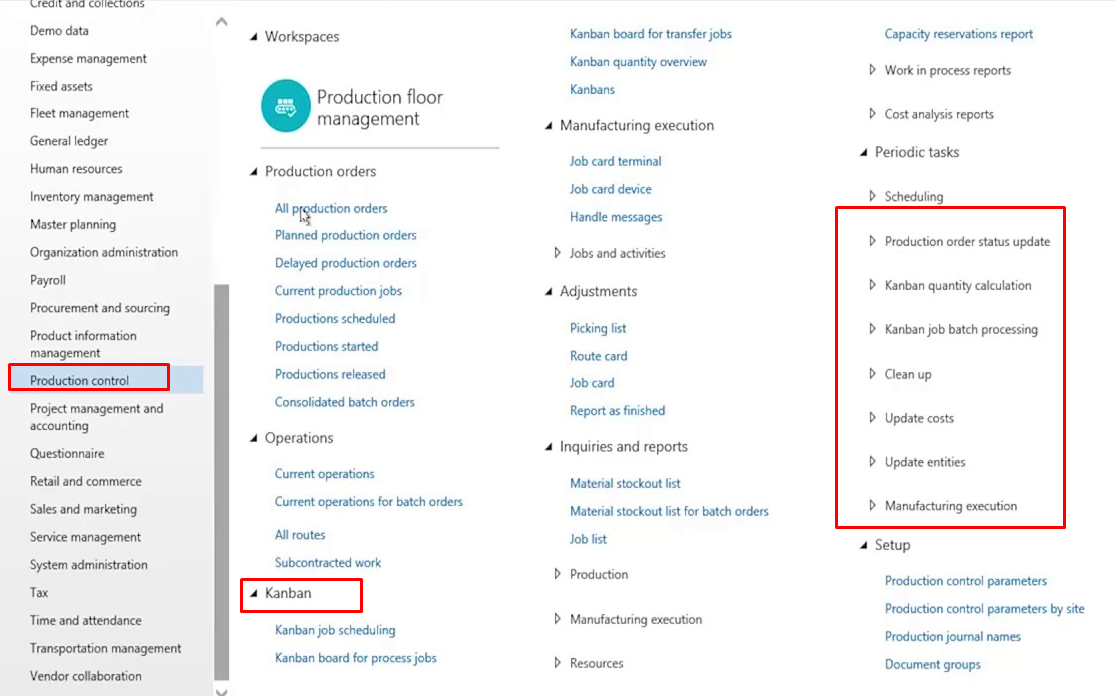

Dynamics 365 Supply Chain Management utilises Kanbans to plan, track and fulfil requirements aligned with production flows. Kanban jobs are generated based on defined Kanban flow activities when creating Kanban.

Kanban rules help to define when Kanban is generated and how requirements are met. Two types of Kanban rules are manufacturing rules for processing Kanban jobs and withdrawal Kanban rules for transferring Kanban jobs.

Replenishment strategies include fixed quantity Kanban rules, master planning generates scheduled Kanban rules to replenish requirements and event Kanban rules are tied to specific needs.

Tracking and Managing Kanban Operations

Dynamics 365 Supply Chain Management provides tools and real-time visibility to monitor and maintain the status of manufacturing and logistical activities governed by Kanban rules. It facilitates efficient planning, prioritisation and execution of the following tasks:

The diagram below shows the kanban process and how it is used.

- The Kanban Job Scheduling overviews Kanban jobs, status, and capacity consumption. Tasks such as changing job status, rescheduling to different periods, and monitoring load can be performed

- The Kanban board for transfer jobs overviews ongoing transfer jobs. Tasks include updating picking lists, starting, and completing transfers and other related actions

- The Kanban board for process jobs supports the production flow by providing an overview of current situations in work cells. Tasks include prioritising, picking, and manufacturing Kanbans, with optimal barcode scanning for reporting. Incorporating Kanbans Jobs with Supply Chain Management Operation

- Kanban jobs within Dynamics 365 Supply Chain Management are seamlessly integrated with various inventory and warehouse processes. Picking activities are performed to replenish materials required for fulfilling Kanban job demands

- Printing and circulating Kanban cards and picking lists support the representation, tracking and registration of Kanban jobs within the warehouse and on the production floor. Bar code scanning facilitates efficient inventory management and reporting of Kanbans

- Lean manufacturing also supports purchasing and invoicing processes related to subcontracted activities. Periodic purchase orders and receipt advice can be created to streamline the procurement and invoicing of services

What are the benefits of Dynamics 365 Lean Manufacturing?

Lean manufacturing strives to eradicate the waste in your industry, which can be idle workers, ineffective processes, and unused materials. From increasing profits to providing customer benefits, lean manufacturing in Dynamics 365 helps you in the following ways.

- It enhances manufacturing processes and efficiency, leading to better product quality

- It allocates resources efficiently, leading to improved productivity

- It reduces costs by addressing excess inventory, overproduction and process flow inefficiencies with automation, inventory tracking and production scheduling

- It fosters real-time collaboration and alignment across teams and business areas, promoting efficiency in lean manufacturing workflows

- Better lead time improves customer service, leading to customer satisfaction and retention

- It helps reduce waste, saving resources such as valuable time and money

Conclusion

You are missing out on many growth opportunities if you are still uncertain about leveraging lean manufacturing. Gone are the days when excess inventory, idle workers and inefficient workflows hampered your business outcomes and growth.

With lean manufacturing in Dynamics 365 Supply Chain Management, you will embark on a journey to create a waste-free environment. By modelling your manufacturing and logistics processes as production flows, you will identify bottlenecks and streamline operations for unconditional growth.

Our experts at Dynamics Square, with a deep understanding of your industry, can tailor lean manufacturing in Dynamics 365 to meet your specific needs. With years of experience, we can bridge the gap between your business goals and technological advancements to deliver customised results.

Witness a scalable transformation

Experience real-time synchronisation and flexibility with a consistent view across your business.

Disclaimer– “All data and information provided on this blog is for informational purposes only. Dynamics Square / MPG Business Information Systems Pvt. Ltd. makes no representations as to accuracy, completeness, currentness, suitability, or validity of any information on this site and will not be liable for any errors, omissions, or delays in this information or any losses, injuries, or damages arising from its display or use.”

.jpg)